CARBOREMOVER - "C"

The product like "Carboremover-C" to especially take care of post-burner problems of Boiler and Thermopack. Even after the usage of Fuel Additives containing 'Combustion Catalyst' and Sludge Conditioners', it is observed that various problems are faced in flue path. The Post Burner problems are normally found in those installations where Solid Fuel is burnt.'

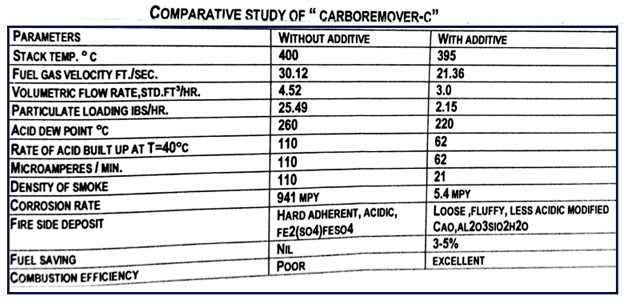

In Solid burning system, where coal or bagasse is not burnt in pulverized form, the combustion process is not proper and remains incomlete even after maintaining very high level of Excess Air. Due to incomplete combustion of Solid Fuel, unburnt carbon particles remain in flue path which are either carried away to chimney or most of the times stick to tube surface. Sometimes due to fusion of ash particles, a sticky adherent layer is formed on tube surface where carbon particles go on accumulating causing various ill efects as listed below.

- Heavy soot deposition

- Soot Fire & Stack Fire

- Corrosion of tube surface

- Inefficient heat transfer

- Overheating of tube

- Excess fuel consumption

- Reduced efficiency of Boiler

- Frequent shut downs for cleaning of flue path

The phenomenon of Soot fire / Stack Fire occurs when accumulated unburnt carbon particles in flue path. whose ignition temperature is already reached, get ignited. This undesired burning of fuel particles near super heater tubes or convection zone tubes causes overheating of tube material and may disturb the circulation of boiler water.

To overcome above-mentioned problems and for smooth & safe working of boiler, we need to improve the combustion process which will ensure trouble free burning of coal. Our product carbremover-C works in such a way that the various problems related to combusion process and combustion products are eliminated. The detailed process of Carboremover-C action is described on the next page.

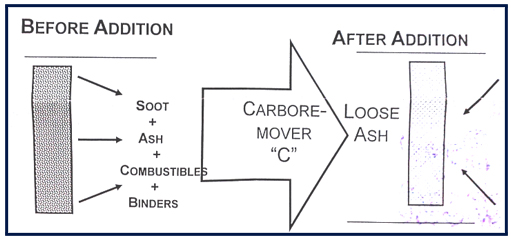

Before Addition :

When coal is burnt in furnace (even with sufficient excess quantity of air), there is always generation of unburnt carbon particles, ash particles and soot which due to air draft travel through flue path and tend to accumulate on tube surface as shown in figure. These deposits consist of Soot, Ash, Combustibles and Binders among which binders keep all these contents together adhering to tube surface. Gradual accumulation of these deposits affects heat transfer and causes overheating of tube. Also there is always possibility of fusion of ash particles resulting in a sticky layer on tube surface thus more worsening the condition.

After Addition of 'Carboremover - C'

When a properly proportioned quality of Carboremover-C is applied in furnace, the volatile active agents of this product come in contact with the deposits. The resulting action is as follows.

- Adhesive bond is brocken thus separating ash, soot and combustibles.

- Ash particle structure is modifided thus melting point of ash is increased. This loose ash can either be blown away by soot blower or is carried to chimney by air draft itself.

- Ignition point of combustible particles is reduced to complete combustion process.

Following mentioned are the various benefits achieved after application.

Carboremover - C :

- Reduction in fireside deposits like soot, ash etc.

- Higher heat transfer efficiency due to cleaner tube surface.

- Reduction in corrosion of tube metal surface.

- Easy removal ash particles due to it's changes structure.

- Shutdown frequency is reduced.

- Boiler efficiency is increased as excess air requirement is reduced.

CARBOREMOVER – O

CARBOREMOVER – O is a multi functional blend for prevention of corrosion, scale and carbon deposits caused by fuel oil in boiler. The product instantly reduced the soot, deposit to almost negligible level. It makes emission of the stack very clean & keep the burners & furnace free from soot.

SPECIFICATION

Appearance : Clear redish colour liquid

Odour : Faint

Specific Gravity : 0.950 ± 0.05 gm/ml

ADVANTAGE

- Total combustion of oil without leaving unburn soot or carbon.

- Blowing off & cleaning process avoided as combustion is total.

- The oil mixed with CARBOREMOVER – O can be fired at low fuel temperature.

- Reduce manpower requirement for boiler cleaning.

- Reduce down time.

- Increases boiler availability.

- Improve heat transfer efficiency.

- Significant saving in fuel.

- The boiler efficiency even after one year of use, remain 90% while without addition of CARBOREMOVER-O, it falls to 60% from the initial 90% .

- Without addition of CARBOREMOVER-O flame is longer with high level of particulate deposits.

With CARBOREMOVER-O addition the flame is short & crisp with 50 to 70 % reduction in particulate deposits.

- Keeps the burner, furnace & stack clean & free of soot.

- Reduced stack temperature.

- Increase the heat output per kg of input of energy source.

Neutralize acid and prevent corrosion.

- Disperse the sludge.

RECOMMENDED DOSAGE

Actual dosage depends upon the extent of carbons deposits & boilers operating condition. However, the recommended dose is 0.5 to 0.75 liter of CARBOREMOVER-O for 1000 liters of fuel oil to be added in the day tank before filling.

CAUTION

CARBOREMOVER-O is highly inflammable & should not be exposed to heat & fire. It should not be kept open. Avoid contact with skin. In case of contact wash soap & fresh water. Do not swallow. Keep the container closed & away from direct heat.

PACKING

30 & 50 liters HDPE Carboys or 200 liters drum